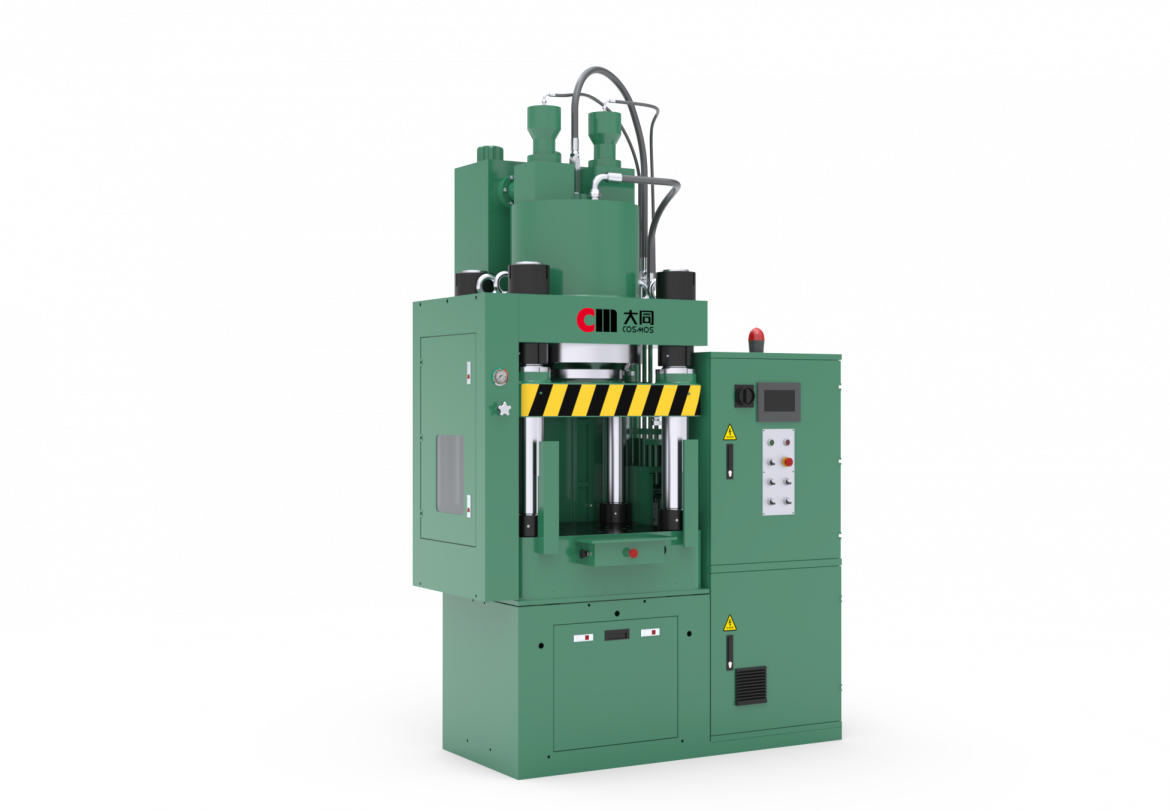

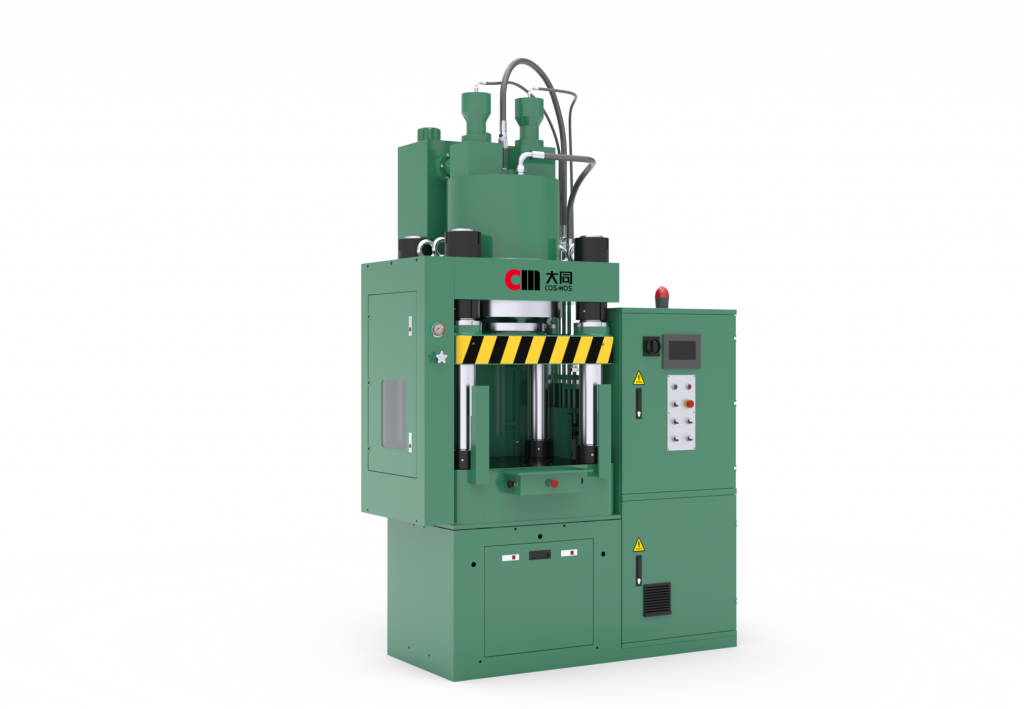

Known for their long-standing experience in the hydraulic press industry, Cosmos Press continues to deliver reliable and efficient solutions for industrial forming and stamping needs. Their servo hydraulic press equipment is built to provide precise, automated performance in a wide range of manufacturing environments. Among their product lineup, the 200 ton hydraulic press is especially recognized for its powerful down-stroke system, ideal for metal forming, powder metallurgy, and non-metal applications.

Integrated Servo Technology for Superior Performance

Cosmos Press integrates servo-driven control systems into their four-column presses to improve energy efficiency, enhance pressure accuracy, and reduce noise during operation. The servo hydraulic press supports programmable settings via a user-friendly interface, allowing operators to adjust speed and force with precision. This makes it suitable for mass production of automotive parts, eyewear frames, and watch cases where repeatability and reliability are essential.

Application Versatility and Customization Options

The 200 ton hydraulic press offered by Cosmos Press is part of a flexible product line ranging from 100 to 5000 tons. Each machine can be tailored to specific production needs, including automatic feeding systems and customized molds. These presses are ideal for manufacturers requiring stable punching force, tight pressure control, and minimal deformation. They also support integration into automated production lines to reduce labor input and increase overall efficiency.

Conclusion: Efficient and Scalable Hydraulic Press Solutions

Cosmos Press provides highly adaptable forming solutions through their 200 ton hydraulic press and servo hydraulic press systems. Built for accuracy, longevity, and ease of operation, their machines serve industries seeking dependable and scalable hydraulic technology. Their engineering team continues to optimize product performance, helping clients meet modern production demands with confidence.